If the table saw is your choice for cross cutting pen stock to length, consider this table saw sled and thin-kerf blade combination. The sled base, cut from ½” baltic birch plywood, measures 6×16”. The support, cut from the same material, to which the hold down clamp is screwed to measures 4×16” and is glued to the base with the back edges flush. As a safety indicator, consider painting a red “caution area” where the blade enters the support. The distance from the clamped-down stop to the inside edge of the blade is determined by the length of the brass pen barrels you’ll be using. To cap it off, use a thin-kerf blade for cross cutting the stock, which minimizes the stock lost to the kerf, allowing the grain in the two matching blanks to match up better for the final product.

Similar Posts

How to Make a Watch Parts Pen Blank By Barry Gross

I chose to make this watch parts blank paired with Penn State Industries new Steampump Pen Kit as a really great Steampunk…

How to make a bottle stopper

By: Marlen Kemmet A good bottle of wine deserves an equally classy bottle stopper. And few of the stoppers available…

An Easy Way to Take Measurements at Your Lathe

We often need to take measurements at the lathe. Rather than constantly worrying about carrying a tape measure, simply use…

Washer does double duty

When turning bottle stoppers and other projects where the outside diameter of the wood to the mating metal part is…

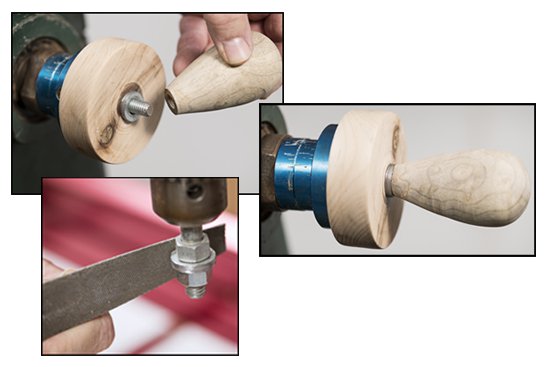

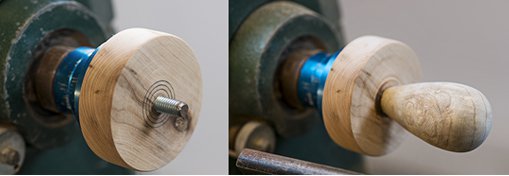

Make an Inexpensive Threaded Headstock

To create your own threaded headstock, mount a piece of hardwood at least 1″ thick to your metal faceplate. Turn…

Is it round yet

Starting and stopping a lathe to check that the blank is perfectly round not only wastes time, but is hard…