No matter how careful you are or how sharp your drill bit, the bottom end of a blank being drilled for a barrel can blow out or chip when the bit exits the bottom of the blank. Unfortunately, a few woods and acrylics are more apt to blow out than others. While repairing a blown-out blank is difficult if not impossible, you can easily work around such stock by simply cutting your blanks longer than needed for the mating tube. For example, if the stock you are drilling is blowing out and you normally crosscut your blanks 1/16” to 1/8” long, cut them ¼” long. After drilling the hole simply re-crosscut the blown-out end to remove the damage.

Similar Posts

Know Your Viscosity at a Glance

With numerous bottles of cyanoacrylate in the shop and aging eyes, it’s easy to grab the wrong bottle for the…

How to Choose the Best-Looking Grain

After ripping your own pen-blank stock square, you don’t necessarily want to start cross cutting from an end of the…

3 Tricks to make glue work for you

1. Keeping glue in its place with this tidy tray Minimize the mess – and frustration – when applying glue…

An Easy Way to Take Measurements at Your Lathe

We often need to take measurements at the lathe. Rather than constantly worrying about carrying a tape measure, simply use…

Cast Your Own Pen Blanks to Make Beautiful Resin Pens

Use our versitile Cast-a-kit for making your own unique, customized pen blanks. By Barry Gross – “Mr. Solid Surface” Let Your…

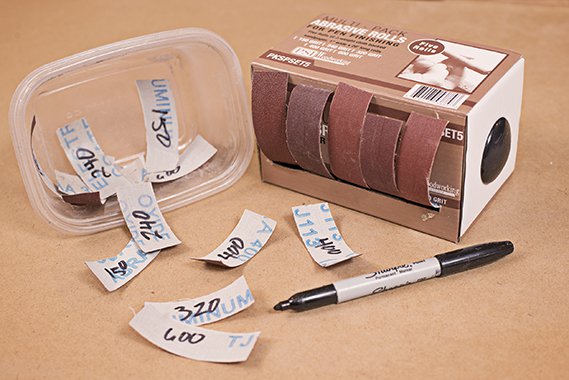

Quit Guessing Grits

Unlike sheet abrasives, abrasive strips don’t have the grits marked on the back side, making it easy to lose track…