When turning bottle stoppers and other projects where the outside diameter of the wood to the mating metal part is important for a flush fit and you don’t have an existing chuck with the necessary diameter, washers make an inexpensive and reusable guide. For example, when turning the bottle stopper shown, the end that mates with the chrome stopper looks and feels best when the surfaces are perfectly flush. To accomplish this, file or grind one or two washers to the same diameter as the mating section of the chrome stopper. Slide the washers over the threaded mandrel. Then, turn and sand the stopper bottom end to same outside diameter as the washers. Not only do the washers provide an exact diameter guide, but they allow clearance to turn and sand the stopper’s bottom end without turning into the auxiliary wood faceplate.

Similar Posts

3 Tricks to make glue work for you

1. Keeping glue in its place with this tidy tray Minimize the mess – and frustration – when applying glue…

7 Steps to making a Pool Cue Kit on your Midi Lathe

A lathe with a minimum of 32” Bed. Turning tools: Spindle Gouge, parting tool and 1” skew essential. The Turning…

An Easy Way to Take Measurements at Your Lathe

We often need to take measurements at the lathe. Rather than constantly worrying about carrying a tape measure, simply use…

Know Your Viscosity at a Glance

With numerous bottles of cyanoacrylate in the shop and aging eyes, it’s easy to grab the wrong bottle for the…

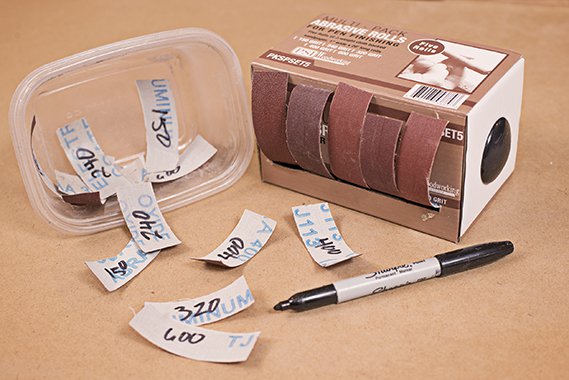

Quit Guessing Grits

Unlike sheet abrasives, abrasive strips don’t have the grits marked on the back side, making it easy to lose track…

Make a Tool and Supply Tray for your Lathe Bed

Keep your turning, sanding and finishing tools and supplies close at hand with a custom-built tray. To make the tray…