No matter how careful you are or how sharp your drill bit, the bottom end of a blank being drilled for a barrel can blow out or chip when the bit exits the bottom of the blank. Unfortunately, a few woods and acrylics are more apt to blow out than others. While repairing a blown-out blank is difficult if not impossible, you can easily work around such stock by simply cutting your blanks longer than needed for the mating tube. For example, if the stock you are drilling is blowing out and you normally crosscut your blanks 1/16” to 1/8” long, cut them ¼” long. After drilling the hole simply re-crosscut the blown-out end to remove the damage.

Similar Posts

How to avoid pen barrel blowouts

“How to avoid pen barrel blowouts” By Barry Gross This happens to the best of us and if someone says that…

Is your Turning Tool Not Sliding Smoothly? How to Fix

In addition to supporting your lathe tools the top edge of a tool rest must be nick and dent free….

Marketing Your Work

How do you get started in selling your pens? The first step is to carry your OWN pen! This may…

How to use a potato to keep glue in its place

Glue has a tendency to get on the inside of brass tubes when gluing them in blanks. That excess glue…

Make Wooden Handles

It’s fun using your lathe but not fun grabbing those skinny metal bar handles on the Toolrest and Tailstock Banjo…

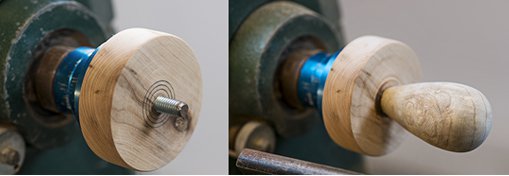

Make an Inexpensive Threaded Headstock

To create your own threaded headstock, mount a piece of hardwood at least 1″ thick to your metal faceplate. Turn…