Articles

Avoid the burn, trim slowly

When trimming the ends of a blank with the barrel adhered inside, use minimal pressure and raise and lower the barrel trimmer frequently to prevent the trimmer from burning the end of the blank and darkening or discoloring the wood. Hard, resinous woods, like those of the rosewood family, tend to burn easily if you trim too quickly. Trim for a second or less and back the trimmer out of the hole to check the depth of cut. Don’t drill too deeply and cut into the brass. To avoid injury never hand hold the blanks when trimming and keep the speed below 500 rpm. If you’re having a difficult time viewing the brass barrel in the hole, a magnifying glass works wonders.

Check out some of the tools and supplies in the article with the links below...

Pen Blank Trimming & Cutting

Stabilized Wood Pen Blanks

Hardwood Pen Blanks

Pen Blank Drilling Center Vise

Crosscutting Barrels

When a micro-thin crosscut is critical

When using finely grained woods, getting a perfect grain match between the upper and lower barrels can make the difference between an average pen and a professional-looking project. Minimizing stock loss when crosscutting is essential to keeping the grain aligned. To minimize wood loss when crosscutting stock, a thin cut is the solution.

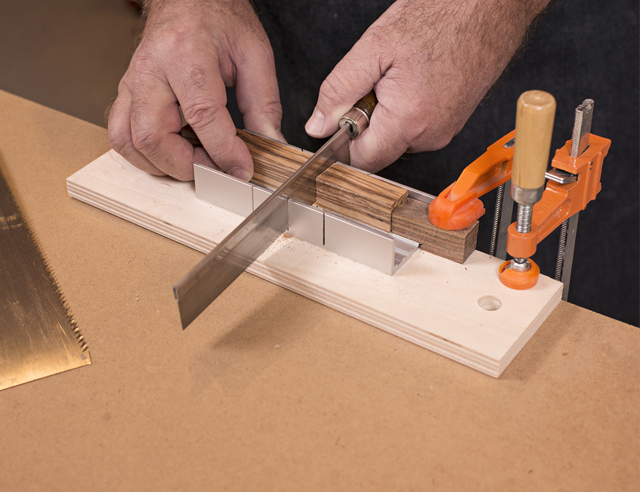

You can crosscut stock on the bandsaw using a blade with minimal set angle. You can also cut them by hand using a fine-toothed saw like the razor saw with a miter box as shown. To make this setup even easier to use, attach a 3x12” piece of ½” plywood to the aluminum miter box enabling it to be securely clamped to a workbench top. The ½” hole in the base allows it to be hung for ease of storage. After cutting, mark the matching ends of the blanks so you will turn and assemble the kit with continuous grain.

Make Wooden Handles

| It’s fun using your lathe but not fun grabbing those skinny metal bar handles on the Toolrest and Tailstock Banjo that dig into your hand.

Here’s a project that serves 3 purposes: 1) Makes using the lathe handles easier and less stressful 2) Provides a fun turning project 3) Makes your lathe look awesome! TAIL STOCK HANDLE: Cut a blank 2” square x 2-1/2” long. Drill a 19/32” hole to 1-3/4” deep. Turn the blank between centers to a profile that fits your palm. Part the wood for a 2” long handle cover. BANJO HANDLE: Cut a handle, 1-1/2” square x 5-1/2” long. Drill a 12.5mm hole to 4” deep. Turn the blank between centers to a profile that fits your palm. Part the wood for a 4-1/2” long handle cover. |

| TIP: If the drill bits required are not available or the hole in the wood is too large, use the next larger bit and wrap a strip of masking tape over the metal to fill up the space for a snug fit. |

|

Marketing Your Work

| How do you get started in selling your pens? The first step is to carry your OWN pen! This may sound silly but I cannot tell you how many pen turners do not advertise their own work by showing off a pen they have made! How do you expect to sell something if you do not have an example of your craftsmanship? Whenever I sign anything or write anything down I always use a pen that I made. By me using my own pen, will lead to a person to ask about the pen I am using and if they don’t ask, I make sure that I show it to them and tell them about it. Be proud of your creations – show your work to anyone and everyone and make sure they know that you made that pen. Hand someone your business card – always have them available to hand out!

The internet and bookstores are loaded with books and articles on how to market and sell your creations. This very brief introduction is by no means going to give you all the answers to success. |

|

| Finding a market for your work… Being a sales manager with over 30 years experience training sales representatives on how to “sell,” the first objective for any good sales representative is to listen. We have two ears and one mouth so why do we talk twice as much as we listen? Listen to what your customer is telling you. Every market is different, what sells in New England may not sell well in Texas and conversely what sells in California may not sell in Minnesota! So, take a moment and conduct your own market research. Visit local galleries, attend craft fairs and join a local woodturning club for ideas on what may sell in a particular area. Getting Established - A fast way to establish yourself is to offer your work for local fundraising. The local ambulance squad was having a fundraiser and I offered to split the proceeds of the sales of my pens as a donation to the ambulance squad. This accomplished three things. First, it was good to give to the ambulance squad. Second, it established my work in the area and exposed me to many people. And third, as a result, many other orders were taken for special pens to be delivered at a later time. Selling at festivals and shows-how do I find out about them? The fastest and easiest way is to search the internet for Craft Fairs and you will see thousands of shows all over the country. There are publications like Craft Master News devoted to art & craft shows so look them up on the internet and find out which ones are local to you. Do you want to do juried art and craft shows (where you send in images of your work to be judged before you are selected) or do you try flea markets and local craft shows that charge a minimal fee for a table. If you send in digital images of your work, make sure that they are crisp and clear and show detail in your work. You may have the nicest pens made, but if the images are of poor quality than chances are you will not get accepted. Whatever you choose just make sure that you check out the promoters of the venue and the area you will be displaying your work. |

| Displaying your work - Lighting is critical! With outdoor shows the lighting is nature and perfect. However, if you are indoors, make sure that you use high intensity lighting and some sort of stair step display to get the pens off the table and elevated! The correct lighting makes your work “pop” with brilliance and is critical when potential customers are looking at your pens. Have a writing tablet with good quality ink available for people to try your pens. You would not purchase a car without driving it; so do not expect someone to purchase a pen if they do not first write with it. Finally, my motto and it is in written in my books and there is a sign in my booth at my fine art and craft shows stating “life is too short to own an ugly pen!” This simply statement gets a reaction from everyone who reads it. Once they read it that will start a conversation and you can engage your potential customer and show them your favorite pen that is in your pocket! |

|

|

|

Sand this way and that

| All pen barrels have to be sanded smooth, but how you do that sanding can make a big difference in the final result. To guarantee a smooth surface every time, start with the finest possible grit. If you've turned a surface that feels smooth to the touch, start with 150 or 240 grit sandpaper. Then, with the lathe spinning at a slower speed, (1,000 to 1,250 rpm), sand across the grain. Stop the lathe and use the same grit to sand with the grain from one end of the blank to the other. Sanding with the grain removes circular scratches. Continue the two-step sanding process with 320, 400, and 600 grit paper. Be careful not to sand the bushings. |

|

| Check out some of our top quality sanding solutions below..... Abralon Sanding Pads Micromesh Sheets Sanding Rolls and Sheets |